본문

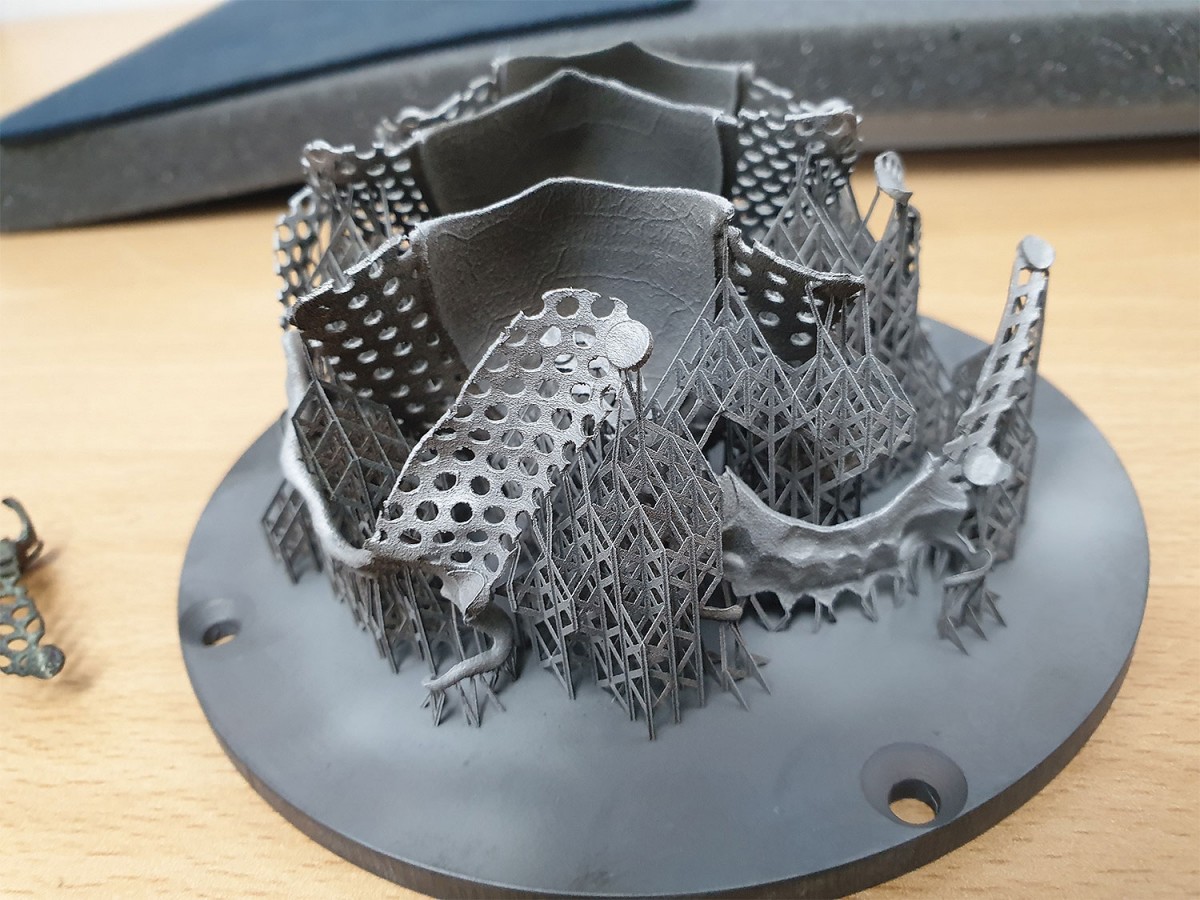

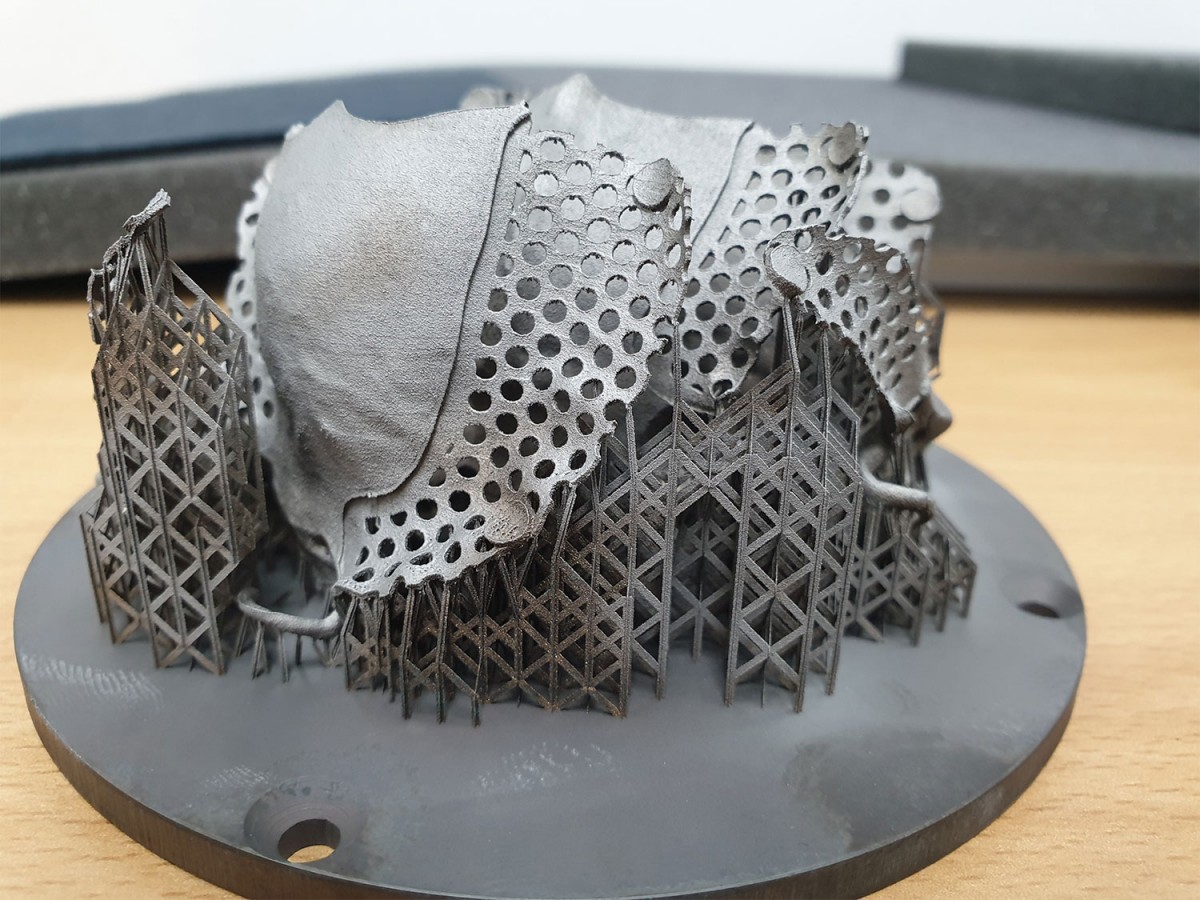

We manufactured dentures to be applied to actual patients using cobalt chromium (15 to 45um) metal powder.

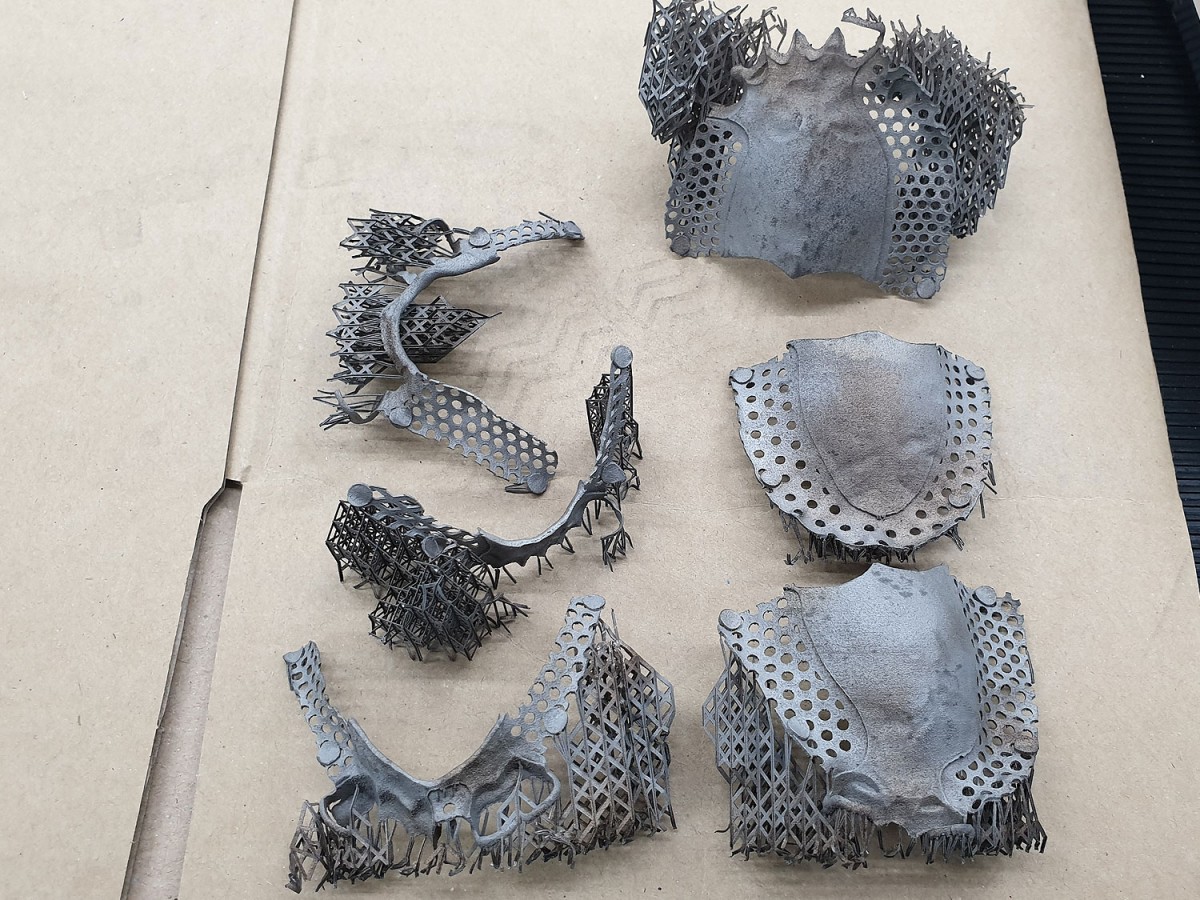

We made 3 sets of 6 dentures, top and bottom, and metal 3D printing took 13 hours.

The design is the data that we worked on at the machine shop

Merain received the data, did the placement and support work, and made it into David 1.0.

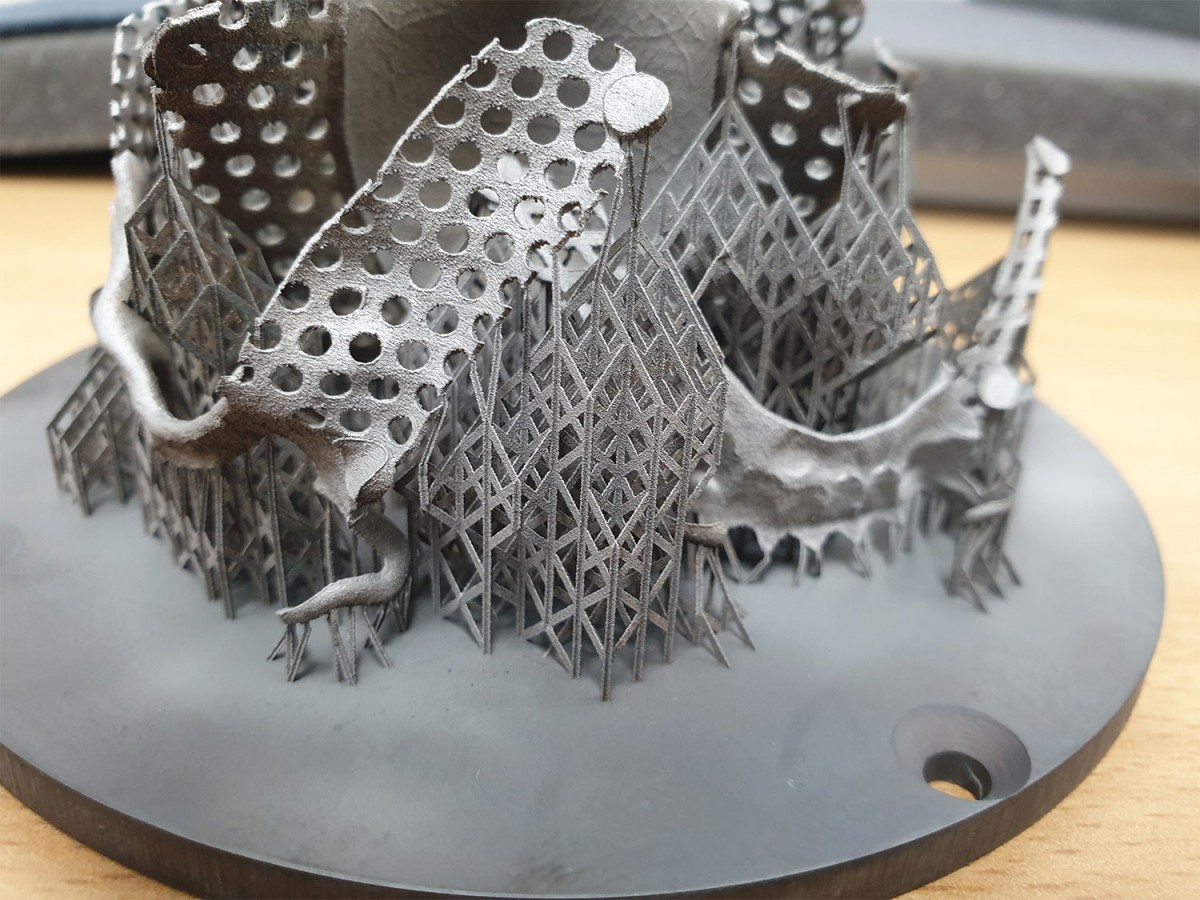

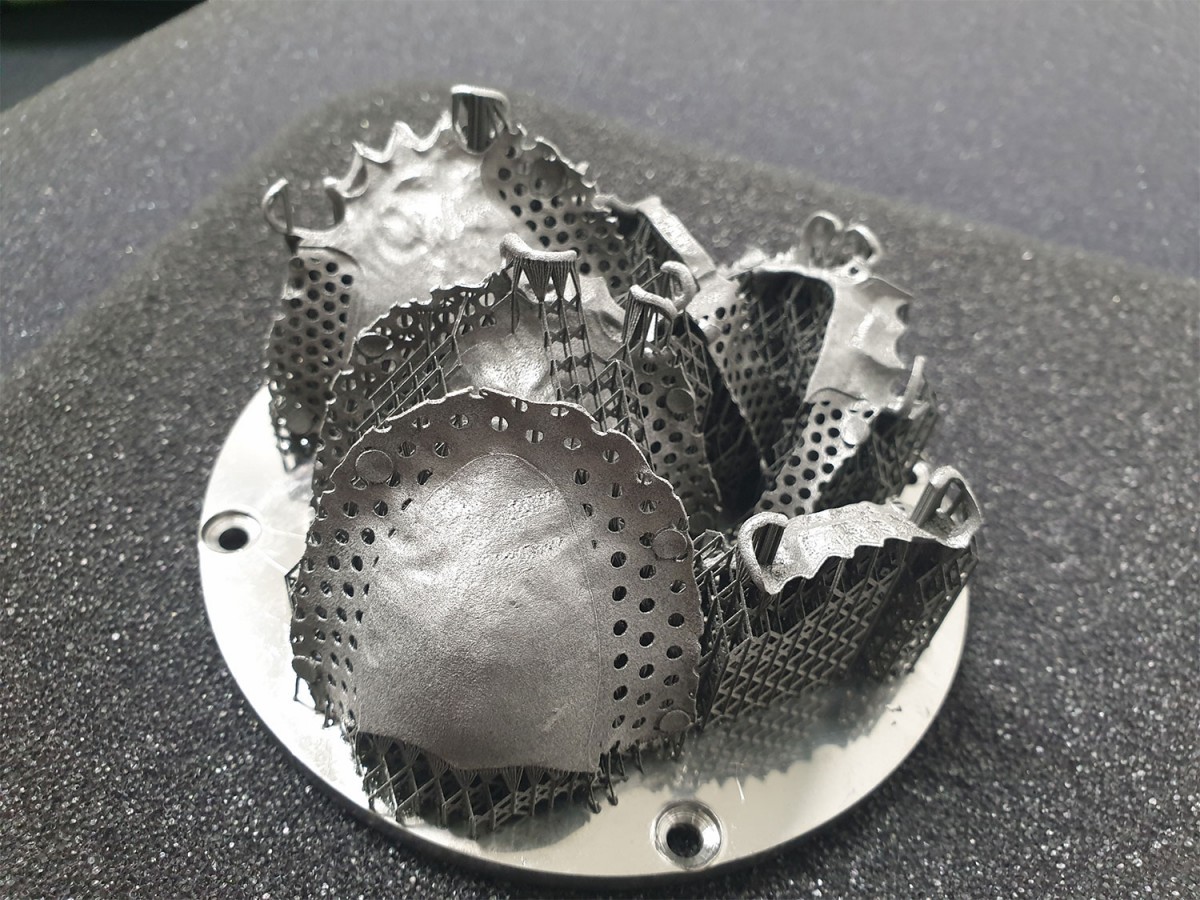

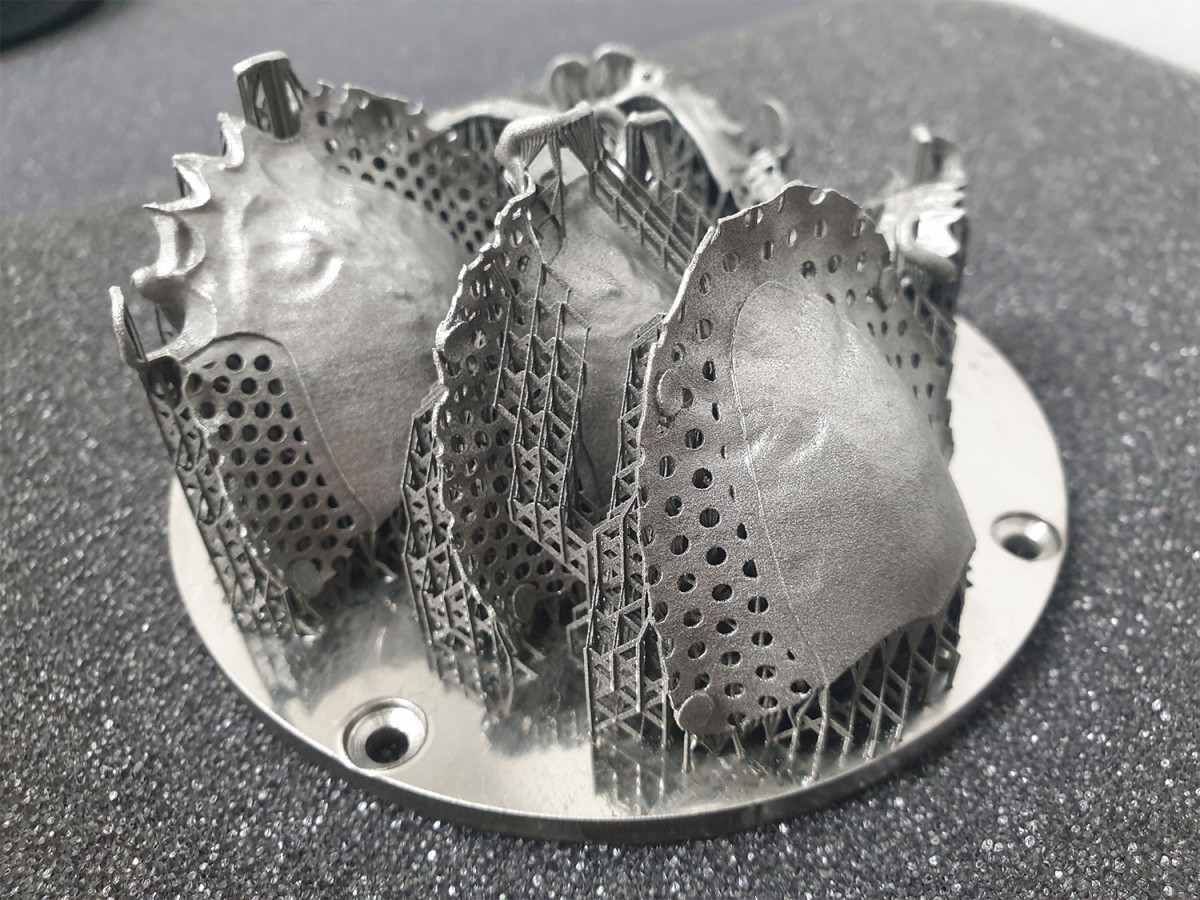

The picture below is after heat treatment. So, you can see a dark place that's slightly burnt

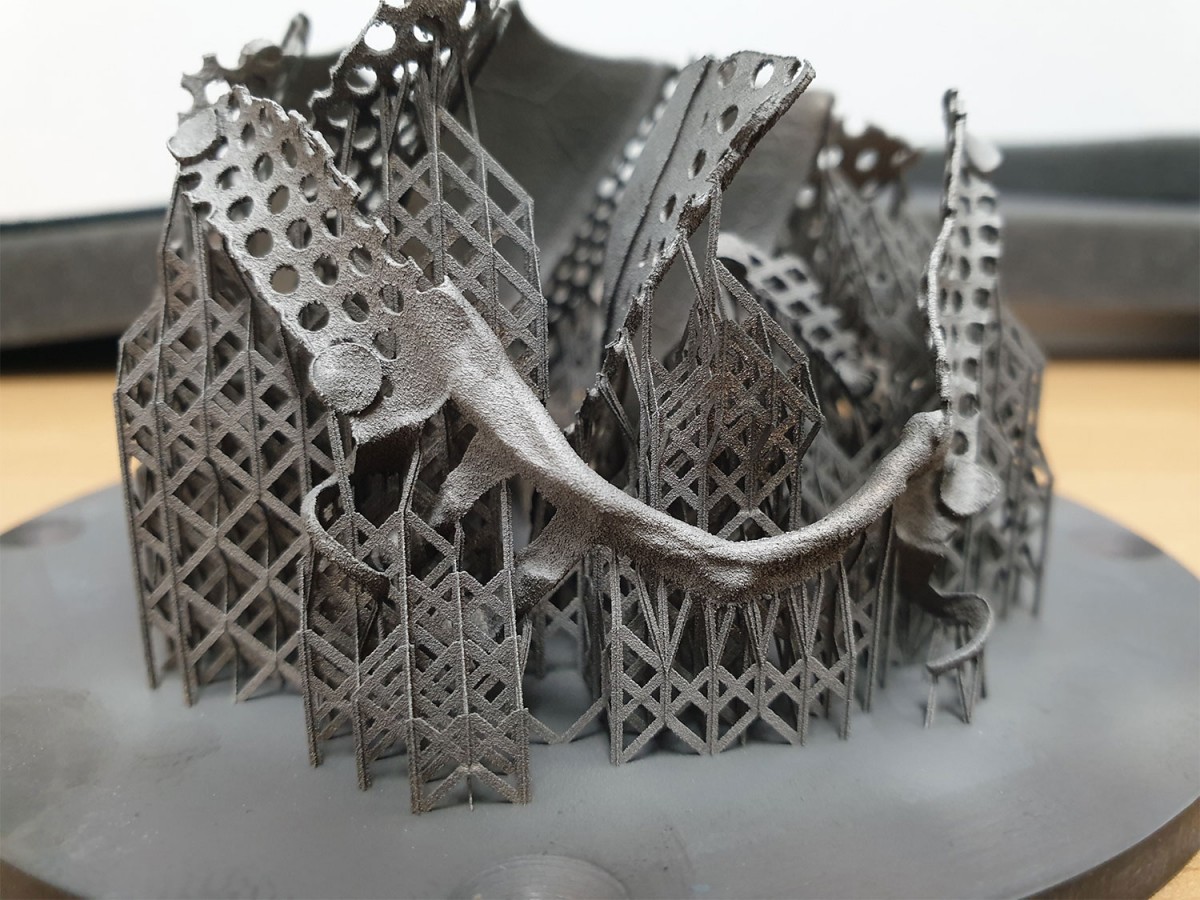

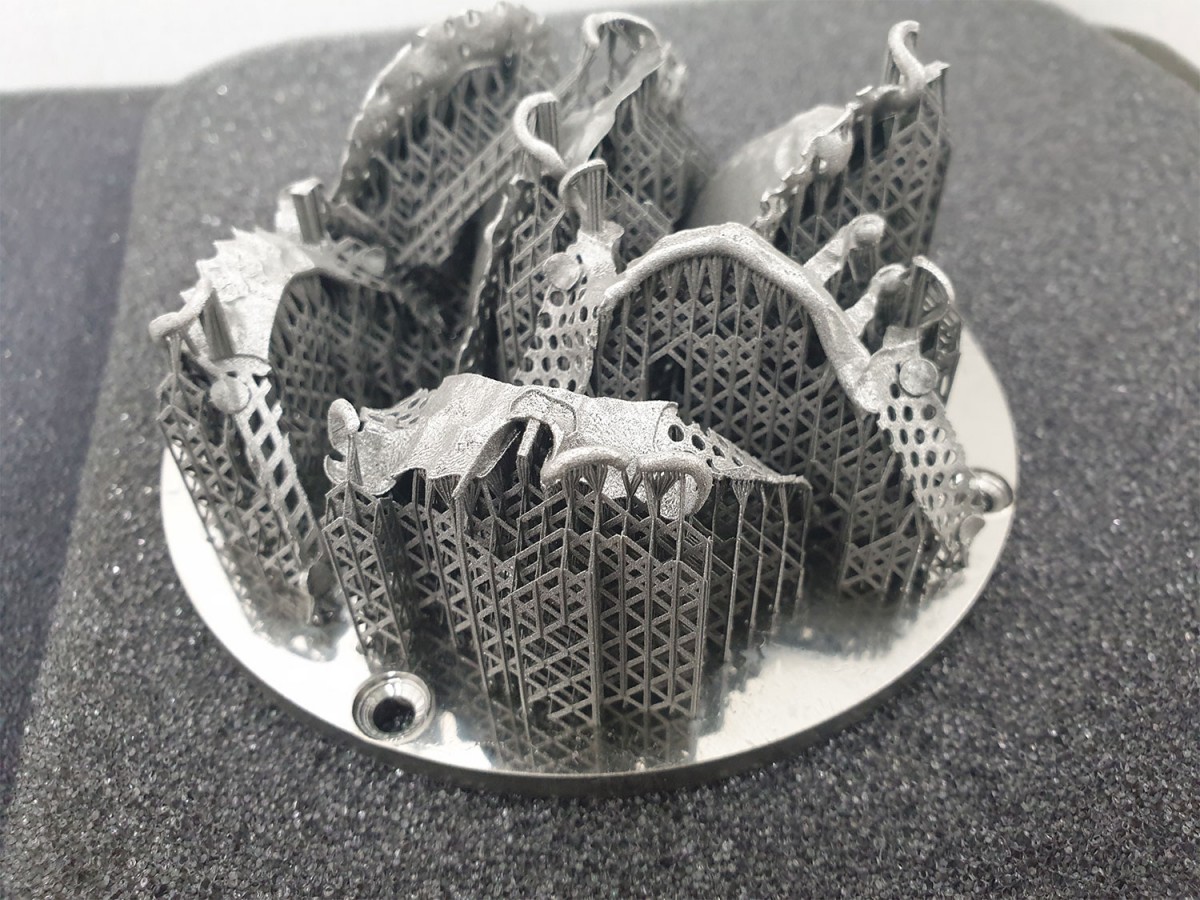

The support is well-made without breaking off. The fact that the support was cut off means that the shape was deformed, but there was no such thing.

The support operation utilized the Denture module of magics print metal.

Support conditions are entered, so support is automatically generated in 2-3 minutes.

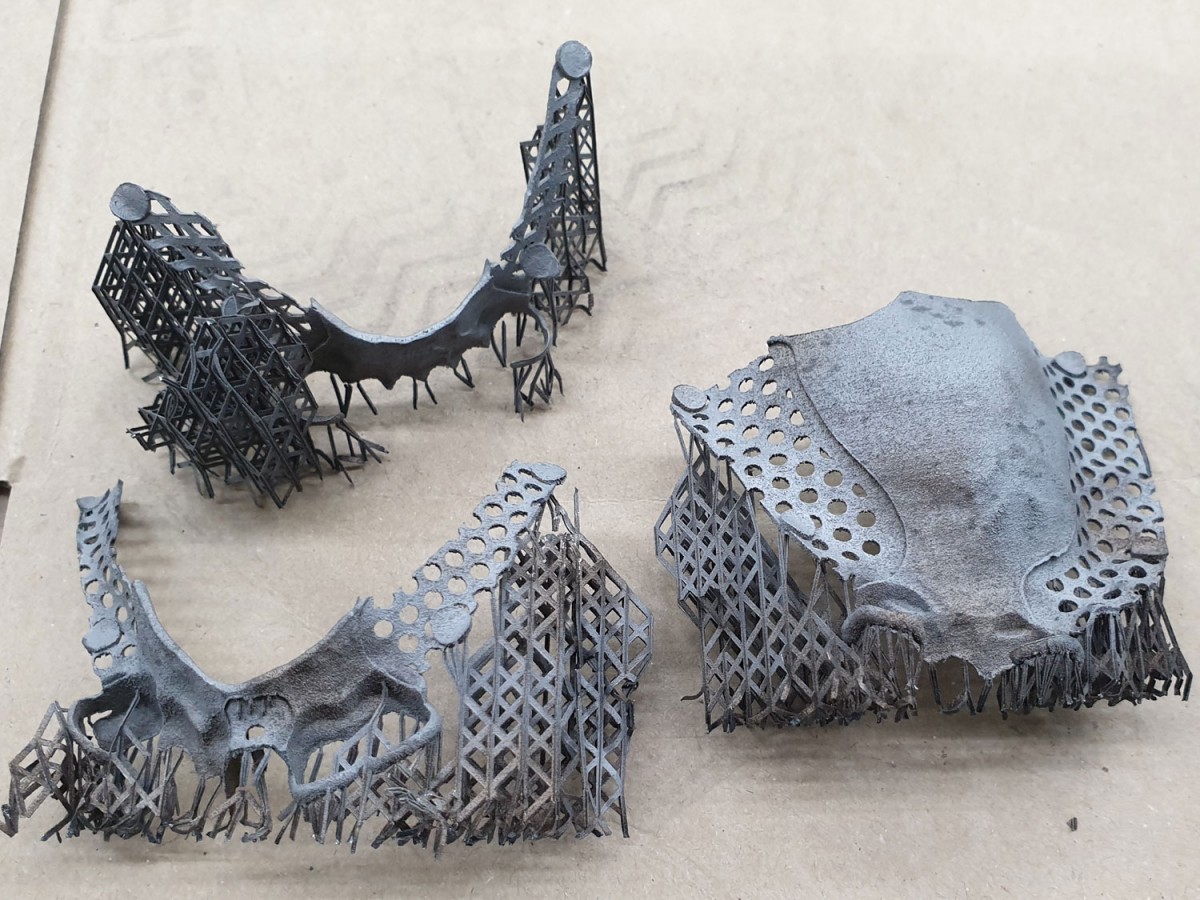

When the heat treatment is completed, the first step of separating the heat treatment from the plate is as follows.

And if you cut the remaining support with a nipper so that it doesn't damage the part, you can send it to the machine shop.

The time it takes to remove the support is 3 to 5 minutes, which is relatively easy to separate.

If you ask me about the production, I will reply.

- 다음글It's made using dental software. 22.02.14