Horse horseshoe metal 3D printing.

작성자

MERAIN

작성일

21-11-05 15:25

조회수

2,608

본문

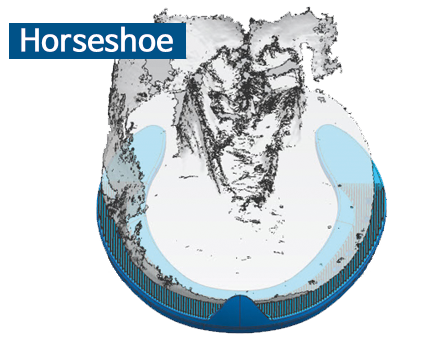

1) What would be good to make horseshoe with metal 3D printing?

The horseshoe is a valid device to prevent horse hoof wear and to prevent various diseases that can occur in the hoof. As explained earlier, horseshoe was traditionally made of iron, but with the development of metallurgy, it was made of various metals according to the horse's main sport.

High-durable steel is used for events that require rapid direction changes such as polo and intense ground stepping, and aluminum is used for horse racing, where speed is the most important. Titanium is sometimes used to reduce weight and increase strength. (Overseas)

Customized production (design is free) Strength, lifetime wear rate, and weight

Aluminum used in horse racing has a light advantage, but its strength is weak, so it wears out before the replacement time every month, causing many problems with bowel preparation. As a solution to this problem, we would like to develop horseshoe horseshoe horseshoe with titanium 2.2 times higher in strength but twice as much as steel, normalize the replacement cycle, and improve the process of customized horseshoe with the knitting. In addition, it can be seen that there is a need for development to use titanium horseshoe, which is convenient for the use of therapeutic horseshoe used to treat various diseases occurring in horseshoe.

But the inevitable problem is the cost. In the actual manufacturing process, the design part was the most problematic part than the cost of the manufacturing itself. Because it's customized, you have to acquire data through the scanning process and design it accordingly.

This is because 3D printing cannot be produced without 3D data. Even if you have some understanding and proficiency in modeling, it is not an easy task because you have to produce four modeling data equivalent to four horseshoe groups. Since modeling is a problem directly related to labor costs, it should be seen that it is practically difficult to 3D printing of horseshoe with a fast replacement cycle every time.

However, if it is a customized horseshoe exclusively for racing horses, I think the story will be a little different. What if titanium is stronger than aluminum? From now on, it's not a matter of cost. Metal 3D printing is perfect for this case. All fields and all parts do not need to be metal 3D printed. Metal 3D printing should focus on customized high value-added businesses.

2) The process of making 3D printing horseshoe.

The process of designing and manufacturing horseshoe scanning is largely as follows.

1. Hoof 3D scan (scanning with a 3D scanner)

2. Customized design (Proceed with NX suitable for curved modeling)

3. Metal 3D printing (Future David 2.0 Metal 3D printing)

4. Verification of tolerance (Provided through a public certification test institution)

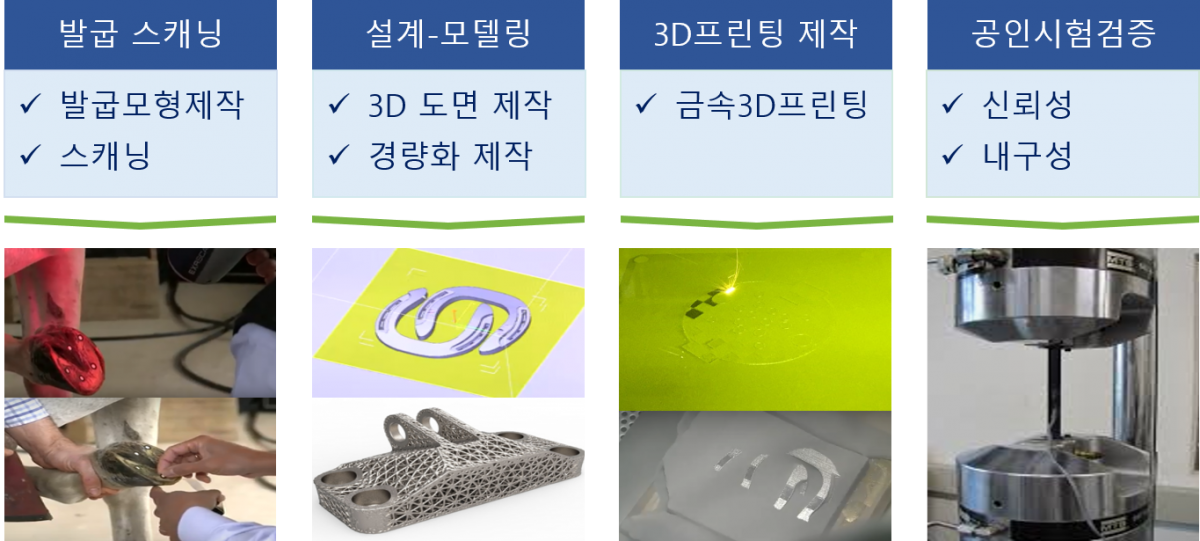

Hoof scanning design-Modeling 3D printing production Certified test verification

Hoof model production and scanning. 3D dwg production. Lightweight production. 3D printing Reliability and durability.

This is how it goes.

Once the metal 3D printer starts operating, it is not easy to stop and redo in the middle, and when it fails, it loses a lot of time and money. This weave production is David 2.0, which uses a PBF metal 3D printer among metal 3D printing. The precision of making the horseshoe is not high, so I think it can be made with a metal 3D printer other than the PBF type.

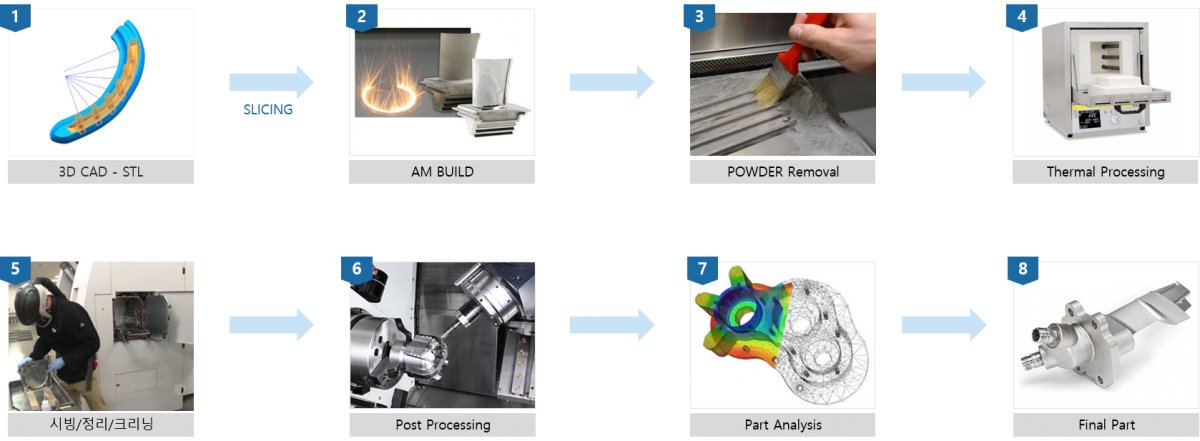

Next is the setting of process variables. It should be set in consideration of the type of material, the performance of the equipment, and the output to be manufactured. First of all, we planned to make the horseshoe made of titanium with a high melting point.

- Laser power - (230w)

- Laser Spot size - (80um)

- According to the spot size, Hatching distance - (80um)

- Layer thickness (The particle size of the metal powder was 40 μm on average from D10 to D90.) - (30um)

- Laser scan speed (It is set in proportion to the laser power.) - (810m/s)

3) Metal 3D printing results.

Metal 3D printing consists of two types of horseshoe with a general type of horseshoe and a grid structure.

The lattice structure cut a specific part from the 3D card and constructed the lattice with Materialise 3-matical on that part. This process can be seen as one of the Design for Additive Manufacturing (DfAM) processes. It can be understood that DfAM is designed and designed for additive processing.

4) Production period and weight reduction of metal 3D printing knitting.

It takes about two days to make four horseshoe horseshoe horseshoe 3D scanning, modeling based on scanning data, metal 3D printing, and post-processing. I didn't know exactly how long it would take to make the horseshoe with the existing method, so I couldn't compare it, but I think it's probably made in a ready-made form and heated and beaten it.

The total production time of 4 horseshoe pieces (front foot 2 and rear foot 2) is as follows.

- Scanning and data organization. - 1 hour.

- Modeling time. - 90 minutes.

- lattice structure. - 30 minutes.

- 3D metal printing per unit. - More than 8 hours. (For group 4, 24 to 30 hours)

- Heat treatment. - 4 hours.

- Post-processing: 1 hour (usually time to remove support).

* In the case of the horseshoe, surface treatment is not required, so it can be finished with the degree of support removal.

Considering that the average weight of horseshoe made of ordinary iron is 300g, it was possible to lighten the weight by 60% to 120g.

5) Precision analysis through scanning.

Most tolerances (dimensions) are within 0.5mm.

6) Production cost of 4 metal 3D printing weaves.

The basis for calculating the cost of metal 3D printing output service is the production cost based on the size, volume, material, and plate prices of modeling data, including labor and control costs such as equipment usage fees, heat treatment and post-processing. In the case of products with precise and important surface illumination, the cost increases a lot in the post-processing area. If you are in a situation where you need to scan or if you need to model, there will be an additional cost. Scanning and modeling have a labor cost ratio of 100%, and in the end, it is concluded that in order to lower the manufacturing cost, as many parts as possible must be selected at once.

In the case of four horseshoe, it is usually about 500,000 won at the beginning of each horseshoe, and if the same product is continuously produced after that, 200,000 won to 300,000 won would be appropriate for metal 3D printing costs. Of course, it is when 8 to 16 pieces were produced at once. And you shouldn't think that the more expensive materials you use, the more expensive it will be. Printing costs vary greatly in post-processing depending on the purpose and use.

7) Conclusion.

We confirmed that it fits well with horse hoofs, but we couldn't proceed anymore because we didn't have enough time to check the actual horse's walking or shortcomings. Through this production, the production of racehorse horseshoe for special purposes is successful. It was well attached to the horseshoe and realized more than 60% of weight reduction through DfAM design. Metal 3D printing cannot be applied to all horse hooves. And I don't think that will happen in the future, but I think that metal 3D printing technology can bring the best added value if it proceeds with consideration of the target, purpose, and cost to be applied.